Protection &

Control Panels

Designed to your exact specifications

Panelmatic builds protection and control relay panels to exact customer specifications, assembling each unit from the provided drawings, bill of materials, and project requirements. Customers count on Panelmatic for repeatable workmanship and disciplined wiring practices that match the design intent. That consistency is what buyers value most because it reduces commissioning time, supports predictable performance, and helps avoid rework or field risk.

Relay Panels

Key Features and Advantages

- Built exactly to customer specifications, including all drawings and wiring requirements.

- Provide protective functions such as operating breakers, disconnects, alarms, and indication.

- Constructed with consistent wiring quality, disciplined assembly, and clear documentation.

- Evaluated by customers for wiring craftsmanship, documentation standards, and facility organization.

- 75% percent of all relay panels Panelmatic manufactures are integrated into PDCs, reducing field work and providing a single-source solution.

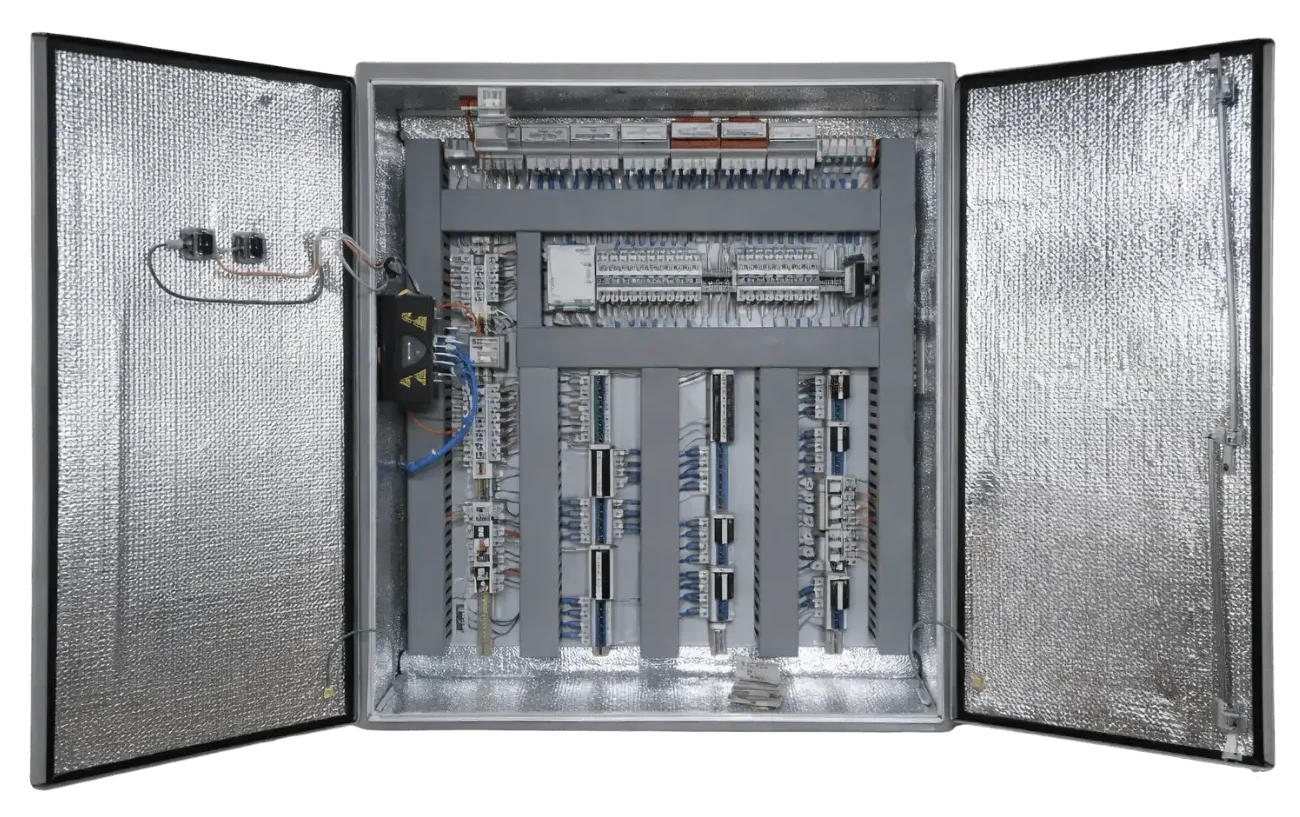

Industrial Control Panels

Key Features and Advantages

- Support manufacturing, material handling, food and beverage, utilities, and other industrial processes.

- Scale from one-off builds to complex, high-volume, large-scale programs.

- The internal controls team supports programming, design, integration, and startups for full project delivery.

- Typical lead times are six to eight weeks for smaller ICPs, with larger schedules set by project scope.

- Built with consistent wiring quality, accurate documentation, and repeatable manufacturing practices.