In hazardous environments, electrical equipment must be protected from explosive gases, dust, and vapors. A Type Y purge system is a vital solution that helps safeguard electrical enclosures by reducing internal pressure and replacing hazardous gases with clean air or inert gas. This article explores how Type Y purge systems work, their key components, as well as the industries that rely on them. In addition, this article covers installation considerations, regulatory compliance, and best practices for maintenance.

What Is a Type Y Purge System?

A Type Y purge system is a hazard mitigation solution that protects electrical enclosures operating in Class 1, Division 1 hazardous areas. These environments are characterized by the presence of explosive gases, vapors, or dust that pose a significant risk of ignition. This system allows for the safe use of Division 2–rated enclosures in more hazardous Division 1 environments without compromising performance.

The system operates through three key mechanisms.

- Flushing hazardous gases out of the enclosure: The purge system introduces clean air or inert gas into the enclosure to displace and also expel any hazardous substances present inside.

- Maintaining positive pressure: Once the enclosure is purged, the system sustains a positive internal pressure to prevent flammable gases from re-entering. This ensures that the environment within the enclosure remains safe for operation.

- Providing a controlled environment: By creating a stable and hazard-free atmosphere inside the enclosure, Type Y purge systems allow electrical components to function safely without the risk of explosion or fire.

Key Components of a Type Y Purge System

A well-designed Type Y purge system includes several critical components:

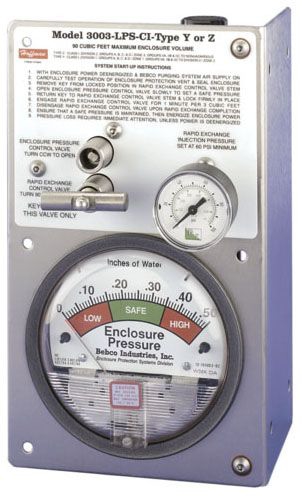

Control Unit

The control unit is the central element of the Type Y purge system. It manages the purge process, monitors system parameters, as well as ensures compliance with safety requirements. Advanced control units provide automated functionality, visual indicators, and remote alarm outputs for enhanced operational efficiency.

Pressure Regulator

The pressure regulator maintains a consistent flow of clean air or inert gas into the enclosure during purging and pressurization. Proper regulation is critical to achieving the minimum pressure requirements to prevent flammable gases from entering the enclosure.

Solenoid Valves

Solenoid valves control the release and regulation of purge gas into the enclosure. These valves provide precise operation, ensuring efficient purging while maintaining system integrity under varying environmental conditions.

Pressure Sensors

Pressure sensors continuously monitor internal pressure levels within the enclosure. They detect fluctuations that could compromise safety and trigger alarms if pressure drops below the minimum threshold.

Vent System

The vent system facilitates the controlled release of hazardous gases during the purge cycle. It ensures that expelled gases do not accumulate in surrounding areas, maintaining safety both inside and outside the enclosure.

Alarm Indicators

Alarm indicators alert operators to pressure loss or system faults, enabling timely corrective action without interrupting operations. This feature is particularly advantageous for applications requiring continuous operation in hazardous environments.

How Type Y Purge Systems Works

Purge Phase

The purge phase begins by introducing clean air or inert gas into the enclosure at a controlled flow rate. This process flushes out hazardous gases, vapors, or dust, ensuring the internal atmosphere is free of combustible materials. During this phase, power to the enclosed equipment remains disabled to prevent ignition risks. The flow rate is carefully calibrated to avoid sudden pressure changes that could compromise the enclosure’s structural integrity.

Pressure Regulation

After purging, the system establishes and maintains a minimum positive internal pressure of ≥0.1 inches of water column (as mandated by NFPA 496). This pressure differential creates a barrier against external flammable gases or vapors. Ensuring a stable and safe environment for electrical components.

Monitoring and Control

Pressure sensors continuously monitor internal pressure levels to detect any fluctuations that could compromise safety. If pressure drops below the threshold requirements, the alarm indicators are triggered to alert operators to take corrective action. Unlike Type X systems, which disconnect power during pressure loss, Type Y systems allow operations to continue while addressing the issue.

Operational Authorization

After the purge phase is complete and the system stabilizes, the system authorizes power to the enclosed equipment. This ensures Division 2-rated devices operate safely in Class 1, Division 1 hazardous locations. Once operational, the system prioritizes continuity. If pressure drops post-authorization, alarms activate, but power remains on, enabling uninterrupted performance while corrective measures are taken.

Key Differentiators from Z and X Purge Systems

Compared to Type X Purge Systems

- Type X cuts power if internal pressure drops.

- Type Y maintains operation and triggers alarms instead of shutting down.

Compared to Type Z Purge Systems

- Type Z downgrades Division 2 to non-hazardous.

- Type Y maintains Division 1 protection.

Industries That Rely on Type Y Purge Systems

Type Y purge systems are essential in industries where hazardous environments demand robust safety measures to protect electrical equipment.

| Industry | Application | Hazardous Environment | Type Y Purge System Role |

| Oil and Gas | Offshore platforms, refineries, pipeline control stations. | Explosive atmospheres with flammable gases or vapors. | Protects electrical equipment from ignition risks. |

| Chemical Processing | Instrumentation and control panels in volatile chemical environments. | Presence of reactive substances. | Ensures safe operation by preventing ignition hazards. |

| Pharmaceuticals | Cleanrooms and manufacturing facilities with volatile solvents. | Controlled environments with combustible vapors. | Safeguards sensitive electrical systems from solvent-related risks. |

| Mining | Underground operations with combustible dust and methane. | High risk of dust and gas ignition. | Prevents ignition hazards in mining equipment. |

| Food Processing | Spray drying operations with combustible dust. | Explosive atmospheres from dust. | Protects electrical equipment from dust-related ignition risks. |

Installation Considerations for Type Y Purge Systems

Proper installation of a Type Y purge system is crucial for ensuring its effectiveness, safety, and compliance with industry standards. Below are the key factors to consider when installing a Type Y purge system.

- Enclosure Selection: The enclosure must be compatible with the purge system and designed for hazardous locations. It should meet the requirements for Class 1, Division 1 areas and be capable of housing Division 2-rated equipment. The enclosure must also allow for proper sealing to maintain pressure and prevent leaks.

- Proper Venting: A well-designed venting system is essential to expel hazardous gases during the purge cycle safely. The vent must avoid creating secondary risks, such as the accumulation of flammable gases in nearby areas. Vent placement should also comply with NFPA 496 guidelines to ensure safe operation.

- Air Supply Quality: The purge medium—clean air or inert gas—must be free of contaminants, moisture, and particulates. Contaminated air can damage sensitive electrical components and compromise the system’s performance. Installing air filters or dryers may be necessary to maintain the required air quality.

- Compliance with Codes and Standards: Type Y purge systems must adhere to applicable safety standards, including:

- NFPA 496: Purged and Pressurized Enclosures for Electrical Equipment

- IEC 60079-2: Explosive Atmospheres – Equipment Protection by Pressurized Enclosures

- ATEX: European Union standards for explosive atmospheres

- NEC Article 500: National Electrical Code for hazardous locations.

- Integration with Control Systems: Connecting the purge system’s alarms and pressure monitoring features to centralized control systems enhances safety and automation. This integration allows operators to receive real-time alerts about pressure drops, enabling quick corrective action while maintaining operational continuity.

Regulatory Compliance for Type Y Purge Systems

To ensure safe operation, Type Y purge systems must comply with various industry regulations and safety codes.

North American Standards

NFPA 496

This standard governs purged and pressurized enclosures for Type Y systems. It establishes the minimum positive internal pressure of 0.1 inches of water gauge required for Class 1 areas. It also permits the use of Division 2-rated equipment within properly purged enclosures, which creates significant cost efficiencies for implementation.

Rather than mandating power shutdown during pressure loss, NFPA 496 requires alarm activation. Hence, allowing for controlled responses to system anomalies. The standard also provides specific formulas for calculating appropriate purging cycle durations on the basis of enclosure volume. Moreover, it requires comprehensive documentation of system verification testing to demonstrate compliance.

NEC Article 500

This is the U.S. National Electrical Code guidelines for hazardous locations. It specifies wiring methods, seals, and equipment ratings for Division 1 areas. Interlocks must prevent operation until purging completes, and conduit sealing must prevent gas migration.

International Standards

IEC 60079-2

This is the international standard for explosive atmosphere protection via pressurized enclosures. It defines the “py” (Type Y) pressurization category. It also mandates leak-tight enclosures with quantifiable maximum leakage rates that must be verified through testing. Systems must incorporate continuous pressure monitoring with clearly visible indicators that signal operational status. For Zone 1/Division 1 applications, the standard requires specific validation procedures and documentation. The standard also addresses temperature classification considerations for all internal components to prevent potential ignition sources.

ATEX Directive

This is the European regulation (2014/34/EU) for equipment in explosive atmospheres. It requires Type Y systems to meet Category 2 GD (Gas/Dust) requirements when deployed in Zone 1 environments. Certification must come from recognized third-party entities such as Sira Certification. Products must carry CE marking with specific ATEX identification that indicates compliance with explosive atmosphere protection requirements. Manufacturers must maintain comprehensive technical documentation packages that include detailed risk assessments addressing all potential ignition sources.

Maintenance Best Practices for Type Y Purge Systems

Regular maintenance is essential to keep Type Y purge systems operating efficiently.

| Maintenance Task | Description | Frequency | Purpose |

| Routine Inspections | Check for leaks, pressure fluctuations, and also proper vent operation. | Weekly or Monthly. | Prevents hazardous gas ingress as well as maintains safe pressurization. |

| Filter Replacements | Prevents contamination of electrical components and ensures efficient purging and pressurization. | As required (based on use). | Prevents contamination of electrical components, and ensures efficient purging and pressurization. |

| Sensor and Alarm Testing | Verify that pressure sensors and alarm indicators are functioning correctly. | Quarterly. | Ensures timely detection of pressure drops or faults, which maintains operational safety. |

| Documentation and Compliance Checks | Maintain detailed records of inspections, testing, and compliance certifications. | Annually. | Demonstrates regulatory compliance (e.g., NFPA 496) and supports system audits. |

Managing Hazardous Industrial Environments with Panelmatic

A Type Y purge system is an effective and essential safety measure for hazardous environments where electrical equipment operates in explosive atmospheres. Understanding how it works, its key components, and regulatory requirements helps ensure optimal performance and compliance. Whether in oil and gas, chemical processing, or pharmaceuticals, implementing the right purge system enhances safety and operational efficiency. At Panelmatic, we have decades of experience and a highly trained team, ready to deliver the most efficient and cost-effective solution. Contact us today to discuss the best purge solutions for your electrical system.